Kreg Hinge Cup Drill Jig

Make Fast and Accurate Hinge Holes

TOP PICK: KREG HINGE JIG

IN THIS GUIDE:

› TABLE SAW: DEWALT DWE7491RS

› SHAKER EDGING BIT: FREUD BIT SET

› ROUTER W/TABLE: BOSCH ROUTER TABLE

› HINGE HOLES: KREG CONCEALED JIG

› CABINET HARDWARE JIG: KING & CHARLES

Woodworkers know that the right tools to make cabinet doors make the job easier and improve finish quality, which makes investing in the right tools job number one.

Of course, budget is always a consideration. Since woodworking is a hobby for most, a part-time job for some, professionals have the tools figured out.

In this guide, learn about:

- Which tools are needed to cut cabinet door wood to size

- Tools to flatten panels

- Sanders to produce a professional finish

- Routers and router bits for cabinet door stiles and rails

- And lastly, jigs you’ll need for hinges and hardware

While making cabinet doors isn’t cheap, comparing the cost of a few hundred dollars in tools to the price of cabinets is worth it.

Page Contents

Tools to Make Cabinet Doors

1. Plunge Router for Cutting Cabinet Door Profiles and Panels

See on Amazon Bosch Router

Used for:

- Rail and style grooves

- Raised panels

- Door edges (if mounted in a router table)

I use a Bosch router set into a router table for my cabinet doors. With easy adjustment and ample horsepower with variable speed, it can handle router bits from large to small for all styles of doors.

I’d recommend against a smaller, hand-held router with less than 2HP if you plan on making more than a few doors. While they might be cheaper, they can’t hold up to oversized router bits and aren’t designed for use in a router table.

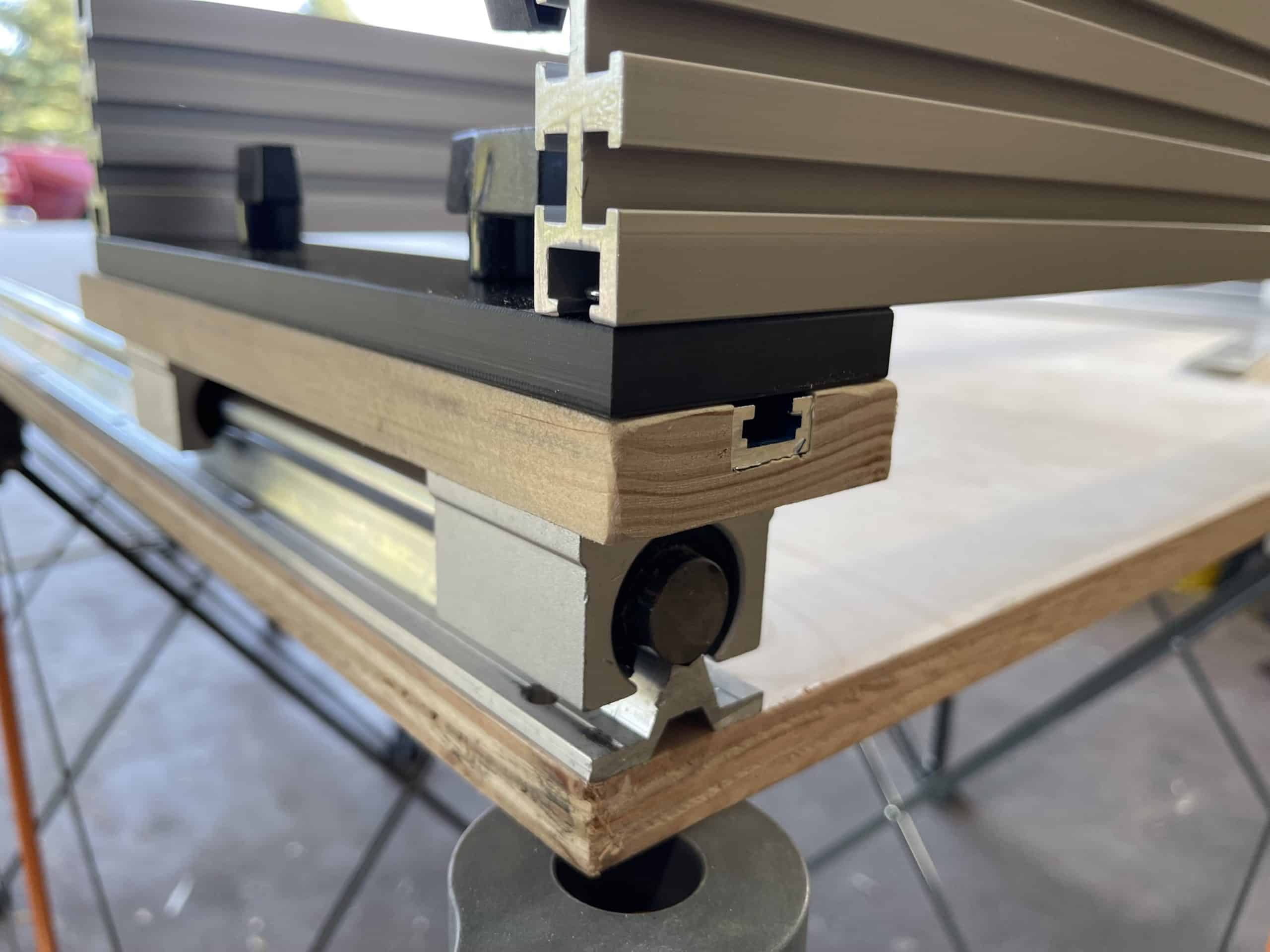

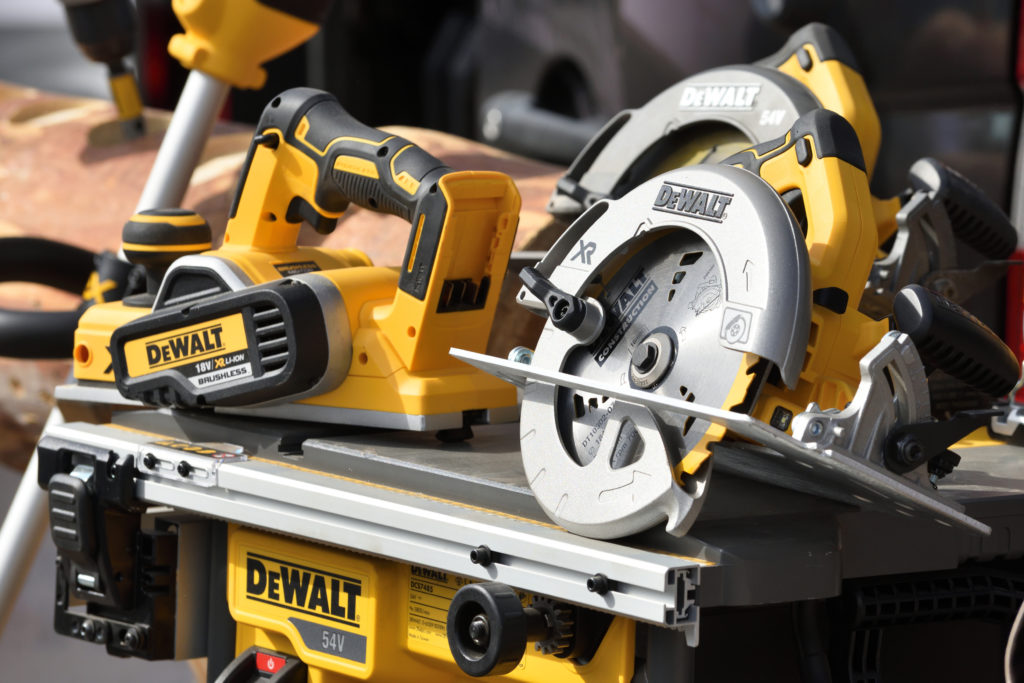

2. Table Saw for Cutting Panels and Rail Material

See On Amazon: Dewalt Table Saw

Door styles:

- All door styles

The table saw is at the top of the list of tools to make cabinet doors. Without one, your design choices will be minimal. How limited? Well, you could only make a flat plywood door using a table saw alternative (the circular saw).

Why is a table saw required? Well, any cabinet door made of the traditional “stile” and “rail” construction requires extensive ripping of wood that makes the door frame.

Three critical uses of a table saw are:

- Ripping wood strips that will form the door panel

- Cutting the stile and rails to the width

- Ripping the finished door panels to width and length

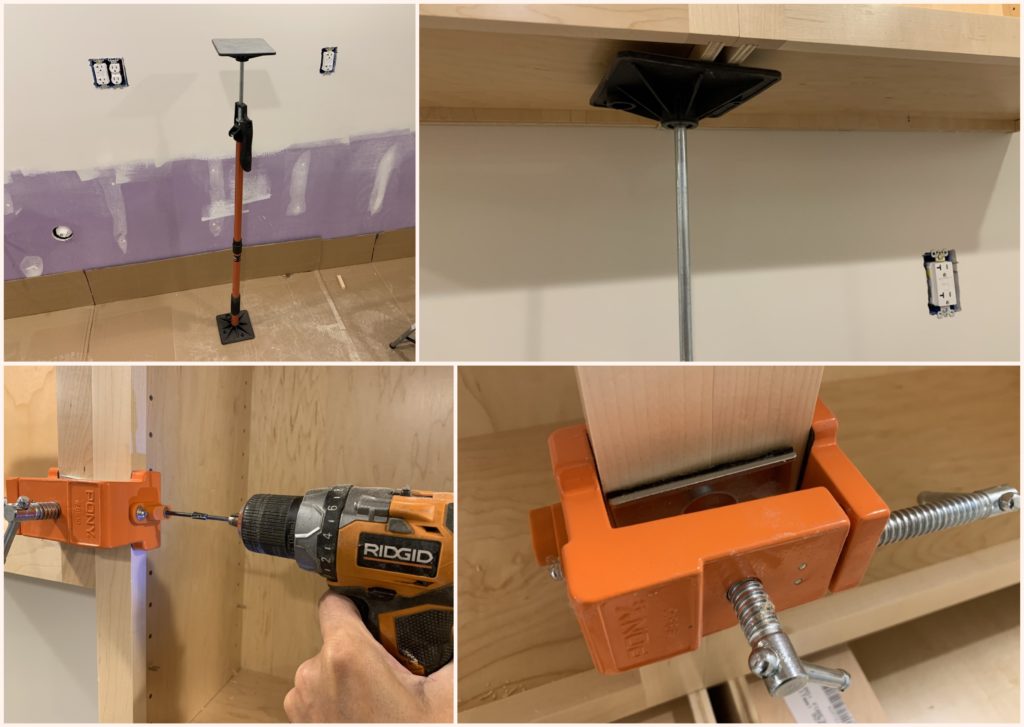

3. Parallel Jaw Clamps to Glue Doors

See on Amazon Pony Parallel Clamps

Gluing the doors together is one of the most essential parts of making cabinet doors.

And while you can use bar clamps, the best option is having a few pairs (honestly, six is the minimum) of parallel clamps.

Here’s why I like parallel clamps:

- Padded faces that won’t compress the cabinet door edge

- They can be tightened snugly, but not overly tight like a bar clamp

- Most brands have cradles that let you securely set the clamp while gluing.

4. Drum sander For a Perfectly Flat Finished Cabinet Door

See on Amazon: JET Drum Sander

Used for:

- Sanding door panels

- Sanding finished constructed doors

- Edge sanding stiles and rails

The premium tools for making cabinet doors will make the finished product the best.

If you are making cabinet doors, then odds are you have making face frames on your list. With its versatility, the drum sander can handle all the sanding tasks on cabinet doors and sand wide face frames, shelf edging, and toe kicks. Of all the tools on this list, the drum sander will make the #1 quality improvement to your finished cabinet.

The drum sander comes in a table width down to 16,” and some range up to 25″. Because you’ll only buy this once, the wider, the better, and spend a few extra dollars.

5. Dado set For Cutting Square Panel Stiles and Rails

See on Amazon: Oshlun Dado Set

Used for:

- Cutting door stiles and rails in mission-style doors

Did you know you can make cabinet doors without a router? With a Dado set, you can make the rails and stiles, cut a back “relief” in your hardwood panels, and skip the router.

You can use plywood instead of a solid wood panel for an even easier door and have dozens of cabinet doors made daily using a Dado and table saw.

6. Raised panel bit to Style Panel Edges

See on Amazon: Yonico Door Panel Cutter

Used for:

- Cutting raised edge in raised panel doors

Coupled with a plunge router and 1/2″ collet (in a router table), a raised panel bit cuts the panel edge. Since every door has a slightly different design, you can pick these up in various cutting patterns.

7. Stile and Rail Router Bit Set

See on Amazon: Freud Bit Set

Used for:

- Cutting grooves for door stile and rails

Stile and rail bits make quick work of door construction. And especially in a router table with a power feed.

You may not have a power feed on your router table (I’ll show you one later). But these bits will power through hardwoods and softwoods. Similar to raised panel bits, you’ll find them in many patterns to fit your style taste.

8. Random orbit sander For Finish Sanding

See on Amazon: Dewalt Random Orbit

Used for:

- Finish sanding of door panels

- Edge and face sanding of door stile/rails

Whether you have a belt or drum sander, you’ll need to remove the coarse sanding lines left by either machine. With a random orbit sander and 120-220 grit sandpaper, you can quickly work this job.

Lastly, don’t apply too much pressure on this sander, or you’ll have “random swirls” in your finished work. Guide the machine across the surface of the wood. It will do the job just fine by itself.

Are you worried about dust? Check out a dust extractor that will connect to hand tools and suck the dust away.

9. Pad sander for Final Sanding

See on Amazon: Pad Sander

Used for:

- Final sanding of the door frame and panel

This is the last sander on the list. When buying the best tools for making cabinet doors, you’ll need to plan for a lot of sanding.

To use this machine, cut a standard sheet of sandpaper in two (lengthwise), fold it over, and install it in the pad sander grips.

10. Sliding miter saw

See on Amazon: Metabo Miter Saw

Used for:

- Cutting door stile, rails, and panels

- Trimming the finished edge of doors to length

When it comes to the best miter saw for cabinet doors, then go big or go home.

Since the radial arm saw and its aggressive, finger-removing style was retired, the miter saw has been the mainstay for even cabinet shops. Because doors can be up to 16-18″ wide, you’ll need a miter saw to cut out to that depth.

Therefore, looking at a miter saw, look at a 12″ blade and the ability to cut a 2×16″.

11. Pipe Clamps for Gluing Panels and Assembling Cabinet Doors

No products found.

See on Amazon: No products found.

Used for:

- Gluing door panels

- Final assembly and gluing of door stile/rails

High-quality cabinet doors are made with real wood panels. And natural wood panels require a few extra tools, including the easy-to-miss pipe clamp.

What’s a pipe clamp? A pipe clamp is – a clamp that screws onto the end of a piece of black pipe on one end and “slides” over the other for an infinitely adjustable clamp. And because of their design, they have massive clamping force.

How many you’ll need is up to your time and the number of doors. Since I prefer to leave door panels clamped for at least eight hours, I have almost 30 pipe clamps from 36″ up to 120″ (they also work great for face frames). For most doors, you’ll use two below and one on top, and while clamping, equally adjust the pressure on the door.

12. Wood Jointer for Ensuring Panel Sticks are Perfectly Flat

See on Amazon: Porter Cable Jointer

Used for:

- Preparing a perfectly straight glue edge on wood panel door strips

- Creating a straight line on rough lumber before ripping in a table saw

If you’ve ever had a table saw blade bind on you in dry wood, then odds are you didn’t run the fence side of the wood through a jointer. Or you’ve glued a wood panel together and had it split later. With a single purpose of making straight edges on wood, the jointer is a must-have when making cabinet doors.

13. Shaper for Making Professional Cabinet Doors

See on Amazon: Shop Fox Shaper

Used for:

- Door stiles, rails, and panels

- Door edges

While the shaper is predominately a tool you’d find in a professional cabinet shop, it has to be on the list. Because a shaper is purpose-built for advanced cabinetry and woodworking, it can quickly work all door stile, rail, and panel jobs.

What’s the catch? Well, a shaper is a significant investment of typically $2000+ for a fully functioning machine, dust collection, and shaper bits.

14. Router Table for Hobby Cabinet Door Making

See on Amazon: Kreg Router Table

Used for:

- Holding a plunge router

- Provides a table and surface for milling door stiles, rails, panels, and edges

While the lines between low-end shapers and high-end router tables are blurring, this is a significant investment if you own a plunge router with the power for cabinet door bits. By working with your plunge router, these tables will provide the fence, flat surface, dust collection, and even support router table feeds for the highest quality door construction.

15. Planer for Making Cabinet Door Panels

See on Amazon: Dewalt Thickness Planer

Used for:

- Rough surfacing of door hardwood or softwoods

- Planing door panels to thickness (~5/8″)

Earlier in this list of the best tools for making cabinet doors, I recommended a drum sander. Well, I still recommend a drum sander, but if you are looking at a combination of a planer and a hand belt sander, you’ll have a workable mix of sander.

16. Cordless Drill for Installing Hardware

See on Amazon: Cordless Drill

Used for:

- Installing door hinges

- Drilling door knob/handle holes

Well, you probably own one, but if you don’t, plan on a cordless drill to install hinges and drill holes for door knobs and handles.

17. Drill Press for Drilling Concealed Hinges

See on Amazon: WEN Drill Press

Used for:

- Drilling European hinge holes

- Cabinet knob and handle holes

You’ll need a drill press for depth control and accuracy with the popular European-style overlay hinges. Because the drill press can be set to a fixed depth, it can drill the 35mm holes required for these hinges without fear of shooting through the cabinet door.

18. Forstner Bit for Cabinet Door Concealed Hinges

See on Amazon: Freud Forstner Bit

Used for:

- Drilling holes for European hinges

Almost all hinges are hidden European hinges that require a (very) large hole to be drilled in your cabinet doors. Just because this step is after the entry is constructed doesn’t make it any less critical. So, purchase your hinges before making the doors to ensure you make the door thick enough.

Frequently Asked Questions

What are the best tools to make cabinet doors?

With the basics of a cabinet door broken down to the stile, rail, and panel, woodworkers will start with tools to cut, shape, sand, and drill. The most common tools are a table saw, miter saw, router and router table, the right router bits, a variety of sanders, and hardware jigs to ensure holes are installed in the proper spot.

What is the best router for making cabinet doors?

The best router for making cabinets is a router that is installed in a router table with a router lift. At the same time, a 2HP router will work fine for cutting rails and stiles; if your plans include raised panel doors, you’ll want to use a larger router over 3HP.

Can I make shaker doors with a dado blade?

Shaker doors can be made with a dado blade and a table saw guide. By setting the dado to the thickness of the panel, the groove can be cut into the rail and stile. Then, the rail ends can be cut using a dado blade, and a table saw jig.

Summary

While building cabinets and cabinet doors is a process that requires planning, the right cabinet door tools, and patience, the result is always rewarding.

- About the Author

- Latest Posts

Eric has been a professional woodworker for over thirty years and has worked in small cabinet shops making everything from kitchen cabinets to hand-made furniture. Now working from a home woodworking shop Eric is sharing his passion for woodworking, tool advice and how-to knowledge from his Minnesota-based woodshop.

Love it //