From wood strip butcher blocks to standard edge-glued tops, there isn’t any substitute for a solid wood top.

Making one, however, is more complex than opting for plywood. But, with a commitment to time, tools, and patience in achieving just the right look, you’ll have a high-quality wooden surface that will last.

Page Contents

Making a Solid Wood Top

From determining the size of the finished top to sourcing lumber and beginning the build, there is a recipe for building a quality finished product.

In this guide, we’ll start from the beginning and cover these steps:

- Wood top types

- How and where to buy hardwood

- Tools and supplies

- Wood joinery methods

- Gluing and clamping

- Cutting to size

- Sanding

- Choosing a finish

- Proper methods of attaching

- Ongoing care of hardwood tops

Step 1: Deciding on a Wood For a Top

There are dozens of mainstream woods to buy when building a solid hardwood top for your project.

So what do you think you could choose?

Well, there are three main criteria that woodworkers will use when deciding on a type of wood:

- Budget. Hardwoods generally cost $5-20 per board foot. This means a 12-inch by 12-inch by 1-inch piece of Cherry at $9 per board foot is $9. A 30-inch by 72-inch top that is a finished 1-1/8 inches thick is (30x96x1.5/144) * 110% for waste = 33 board feet or about $300. That factor boards are 96″ long, and a 1-1/8 finished wood was made from a “6/4” or 1-1/2 rough cut board.

- Looks. The options are endless, from standard domestics like oak or maple to exotics like teak. While many builders look to match cabinets, floors, or trim, other reasons exist to contrast what’s already there.

- Workability. A large top made from a 2-inch thick hard maple stock is gorgeous. But it can weigh over a hundred pounds, is extremely demanding to sand, and staining requires careful removal of all blemishes.

Best Woods for Beginners

You must match the existing wood if your project is from a particular species. However, if you haven’t started down the build path yet, then the following woods are a great place to start:

- Cherry is a highly figured, gorgeous wood that is easy to work with and resists splinters and sands well. This sought-after wood readily accepts stains, darkens slightly with age, and has a timeless look. But the downside of Cherry is it dings and dents easily compared to Maple or Oak.

- Maple is a highly dense, blondish wood known for durability and abrasion resistance. Maple can be made in a “butcher block” style where the wood is face glued and appears like strips. Lastly, Maple finishes nicely with clear finishes or mineral oils but is known to be challenging to stain.

- Pine that has been kiln-dried (not 2x8s from Home Depot) is an excellent choice as it is lightweight, sands easily, and, with proper technique, can be stained just about any color. As a bonus, this wood is usually the least expensive.

Tip: The Janka scale ranks wood hardness and is an excellent guide if a durable top is a top goal. As you read this scale, the higher the Janka value, the denser (and harder to work with) the wood is.

Wood Tops That Require More Skill or Tools

While a solid hardwood top made from Purple Heart seems like a good idea in the hardwood store, this wood is more complicated than Hickory and requires serious woodworking tools to cut and sand properly.

This means a DIY’er should avoid woods like the following unless you are investing in tools, help, or both:

- Exotic woods are generally denser and harder to work with. And some can have harmful or toxic dust that needs to be carefully managed during construction.

- Live edge slabs are fantastic options for a wood top. However, they are cumbersome and require a router sled to flatten correctly. And, if not finished properly, it can warp as the wood is subjected to changes in relative humidity.

- Butcher block or end-grain style tops from any wood are harder to make as they require additional clamps, planning, and wood selection to ensure the long-term integrity of the to.

Calculating Wood Cost

Professional woodworkers know wood is purchased by the “board foot.” And, while the formula is flexible, buying what you need is more challenging.

To keep it simple, however, the formula for finding board feet is simply taking the dimensions of the rough lumber as follows: (length * width * thickness) / 144.

So what does rough lumber mean? It is simply the dimensions before it’s planned (usually 13/16-inch). A 13/16″ board was 1″ thick, a 1-1/4″ board was 1-1/2″, and so on.

Here are a few examples:

- A planed board 13/16″ thick that’s 5-1/2″ wide and 100″ long is calculated as (100 * 5.5) / 144 = 3.82 board feet.

- A planed board 1-3/4″ thick that is 6″ wide and 96″ long is (96 * 6 * 2) = 8 board feet.

After decades of doing these calculations, most woodworkers can look at a board and approximate their cost. Lastly, always feel free to ask and see the math when buying wood to understand what you’re paying for fully.

Tip: Be realistic on budget. Measure the length and width of your project and multiply by $10 for a dimensional wood (2×4) project and $20 for a hardwood top that is 1-1/2 inches thick. A 3′ x 6′ cherry top is 18*$20 = $360 for wood alone.

Where to Buy Wood

- Local hardwood mills. Lumber mills are the best place for the widest variety, and we have over 300 supplies in our hardwood guide.

- Online. Both Amazon and Woodcraft have a great selection of hardwoods and can ship boards up to 72 inches in length through standard shipping.

- Box Stores. While the stock will be limited to usually Maple, Oak, and possibly Cherry, box stores like Lowe’s or Home Depot usually have a limited supply of high-quality wood.

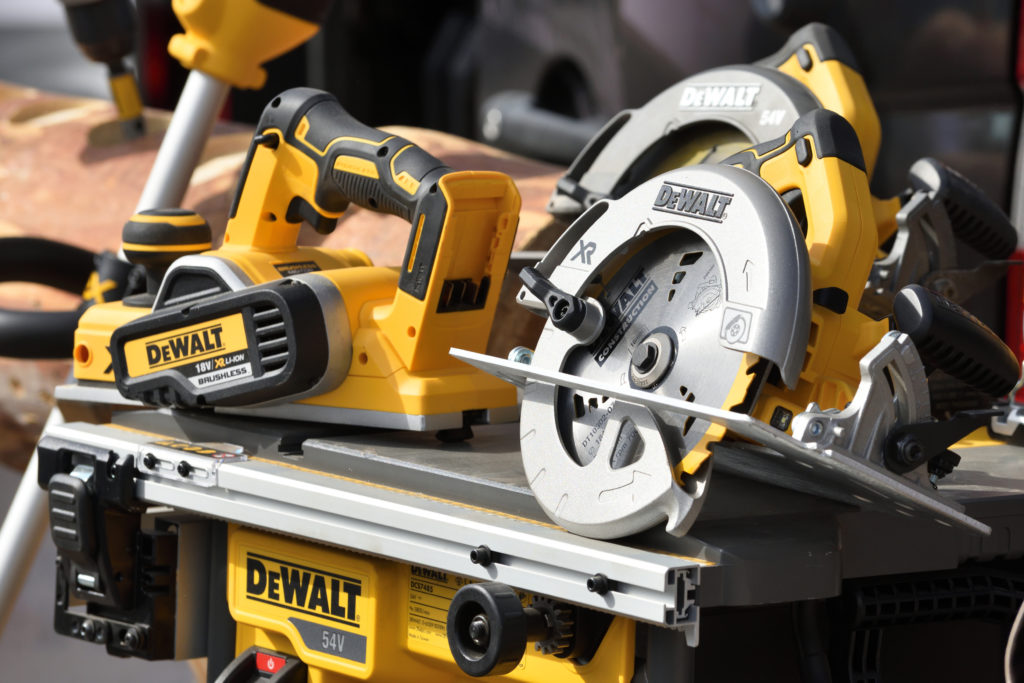

Step 2: Have The Right Tools and Supplies

As you’d expect, the essential tools to make a top include workshop staples like the following:

- Table saw to rip boards to width

- Miter saw to cut boards to length

- Belt sander to flatten and remove planer marks

- Random orbital sander to create a finish-ready surface

- Pipe clamps to glue the panel

- Wood glue (preferably Titebond II for interior tops)

- Glue scraper to clean up excess glue

- Benchtop planer for leveling the wood top

But for a high-quality top, woodworkers will use the following tools to make the project faster and improve quality:

- Drum sander to professionally flatten the wood top

- Track saw to cut the sides and end to length

- High-end sanders like from Festool that have reduced vibration or enhanced stock removal settings

- High-grade sandpaper that uses advanced abrasives and design to avoid swirls and blemishes

Step 3: Pick a Wood Joinery Method

Professional woodworkers know that glue forms a bond harder to break than the surrounding wood. This is why the best and most common way of gluing a wood top is with wood glue, clamps, and some preparation.

However, at times, other options for wood joinery may make sense:

- Bread-board ends are used when opposing grain is used at the end of the wood top. This is an advanced joinery method that requires careful construction to avoid humidity-related cracking later in the tops life

- Pocket hole joints are best used for raw dimensional lumber tops that will not be sanded and where glue squeeze out is an issue

While loose tenon, mortise-and-tenon, and other joints are options, the strength of just glue is a bonus, given its low cost. Of course, you’ll need to supply the pipe clamps .

Step 4: Assembling the Boards

When working with wood, the beauty and frustration can be that no stick of timber is the same.

And, when assembling your project into its final form, that means looking at every stick on all four sides:

- Cut to Length. If you will have excess length, cut the wood to size first and leave 2 inches on either end for waste, splits, and snipe from your planers or sanders.

- Defects. Pick a top and bottom and put defects on the bottom. Most woodworkers will draw a line on the top side of a project to denote “good.”

- Warps. While you’ll never find a perfectly straight pile of even high-grade lumber, if boards warp more than 1/2-inch over eight feet, most woodworkers will reject them and cut them into smaller projects.

- Split ends. These are tricky to spot, but look for splits or cracks and remove them from the finished top area.

Tip: Buy a roll of construction paper and use under your bench or floor (as shown above) to make glue clean-ups easy.

Use Just Enough Glue

The last thing any professional woodworker wants in a project is dry joints. Not only will these weaken the top, but they can also create an expensive redo.

The solution? Use enough glue when applying so that there is a uniform squeeze out of glue when clamping. Then, after removing the clamps, use a wood glue scraper to remove the excess.

Gluing Large Wood Tops

One of the most complex parts of making a wood top is the sheer size of the finished project.

Which for experienced woodworkers with even industrial tools means glue-ups in steps:

- With most benchtop planers 13″ wide, gluing up in 12″ strips allows for a few trips through the planer to reduce the number of joints

- Once your pieces are planed and, if available, run through a wood drum sander, then straighten the edges and glue into the finished top.

However, if you need to glue into a single top, consider a woodworking slab flattening mill that uses a router instead of a planer or sander for a final finish.

Step 5: Cutting the Wood Top To Size

First, if you don’t own a woodworking track saw, buy one before proceeding. These saws are so easy to use, cut with extreme precision, and leave such a clean finish that a miter saw, circular saw, or other methods are just archaic.

So how do you cut a large, expensive wood top? Woodworkers generally follow these three steps:

- Make sure the edges of the top are parallel and straight. If not, use a jointer, track saw with an extended guide, or your table saw to straighten the edge.

- Next, use a large square and (preferably) a track saw to cut the first end to a square. While there are two ends, the best method is choosing the “cleanest” stop with minor splits, cracks, or other deformities.

- Lastly, cut the second end to the finished length. In this step, one trick to check for squareness is to draw a line, then measure from corner to corner. If you have the exact measurements AND your square is reading on, then your top should be within a close tolerance to square.

Step 6: Sanding Wood Tops

Creating a perfectly sanded top is the process’s most time-consuming and error-prone task. After hours of selecting wood, gluing, and trimming to size, the make-or-break step of sanding can be nerve-wracking.

However, by following these tips, you can significantly improve the finished product:

- Utilize daylight or a bright light to see all the imperfections in the wood

- Then, use a grit progression like 60, 100, 150, or 220 with an orbital sander (adjust to your sandpaper collection). Do not skip grits, as this can leave swirl marks

- Always use just enough pressure to control the sander but never push down

- Avoid repeated sanding in one area. Instead, you can just feather in and around in broad areas if one spot requires extra sanding.

- Lastly, inspect the entire wood top with a bright light and from many angles to detect any scratches from lower grits.

Choosing Sanders

Most woodworkers won’t own a planer, drum sander, belt sander, random orbital, and sheet sander.

But you still need to make a high-quality finish. So what are the must-have sanders? Well, consider these when deciding how to approach heavy sanding:

- A drum or wide-belt sander is the best for a large wood surface. These sanders will create a perfectly flat top and minimize hand sanding. However, expect to pay over $1000 for even basic models and as much as $2000 for an 18-inch wide drum sander.

- However, for budget-minded DIY’ers, a good bench top planer for around $500 will quickly remove uneven edges created by glue-ups (in 2, 3, or more pieces).

- Alternatively, a hand-held belt sander (preferably a 4×24) is the “old school” method of flattening wood tops. While slower and more prone to error, this sander, when used with care, will remove glue ridges and create a quality top.

No matter what sander you choose for removing ridges, a quality random orbit and sheet sander are necessary.

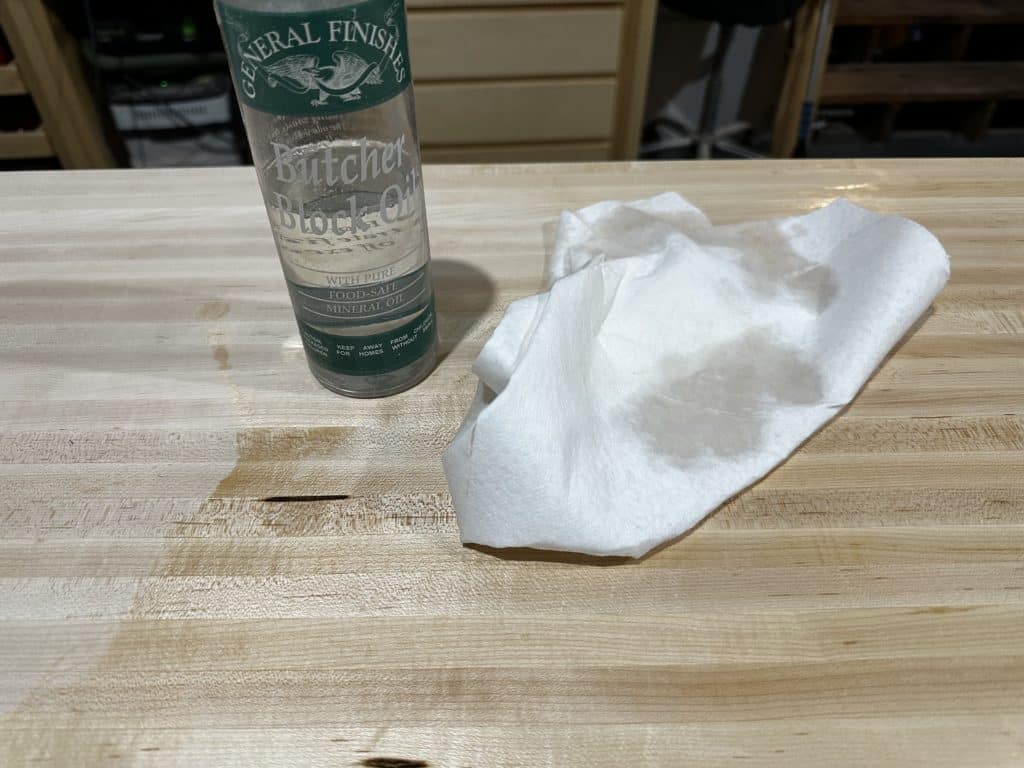

Step 7: Choosing a Wood FInish For Your Top

For some woodworkers applying the finish is the most enjoyable part of the job. But what’s the best wood finish for your top?

While most makers choose based on color, toxicity, or ease of application, the simple answer is there are many options:

- Food safety. Any wood surface in contact with food must use a food-safe finish like mineral or tung oil.

- Durability. If a wood top will be subjected to constant moisture or rough use, then a two-part epoxy finish is usually best.

- Color. Penetrating wood sealers will seep into the grain and provide a rich color for the life of the wood. However, a water-based finish with UV resistance, like a polycrylic, will avoid yellowing and protect the surface.

- Exterior use. For outdoor surfaces, specialty marine epoxy or spar varnish are popular choices. While these finishes may yellow, they provide superior UV resistance to increase their working life.

Finish Both Sides the Same

For both durability and preservation of the wood, it is always best to stain and finish both sides of your top the same. This means applying any penetrating finish evenly, and then the same with any wood sealers or finish coats.

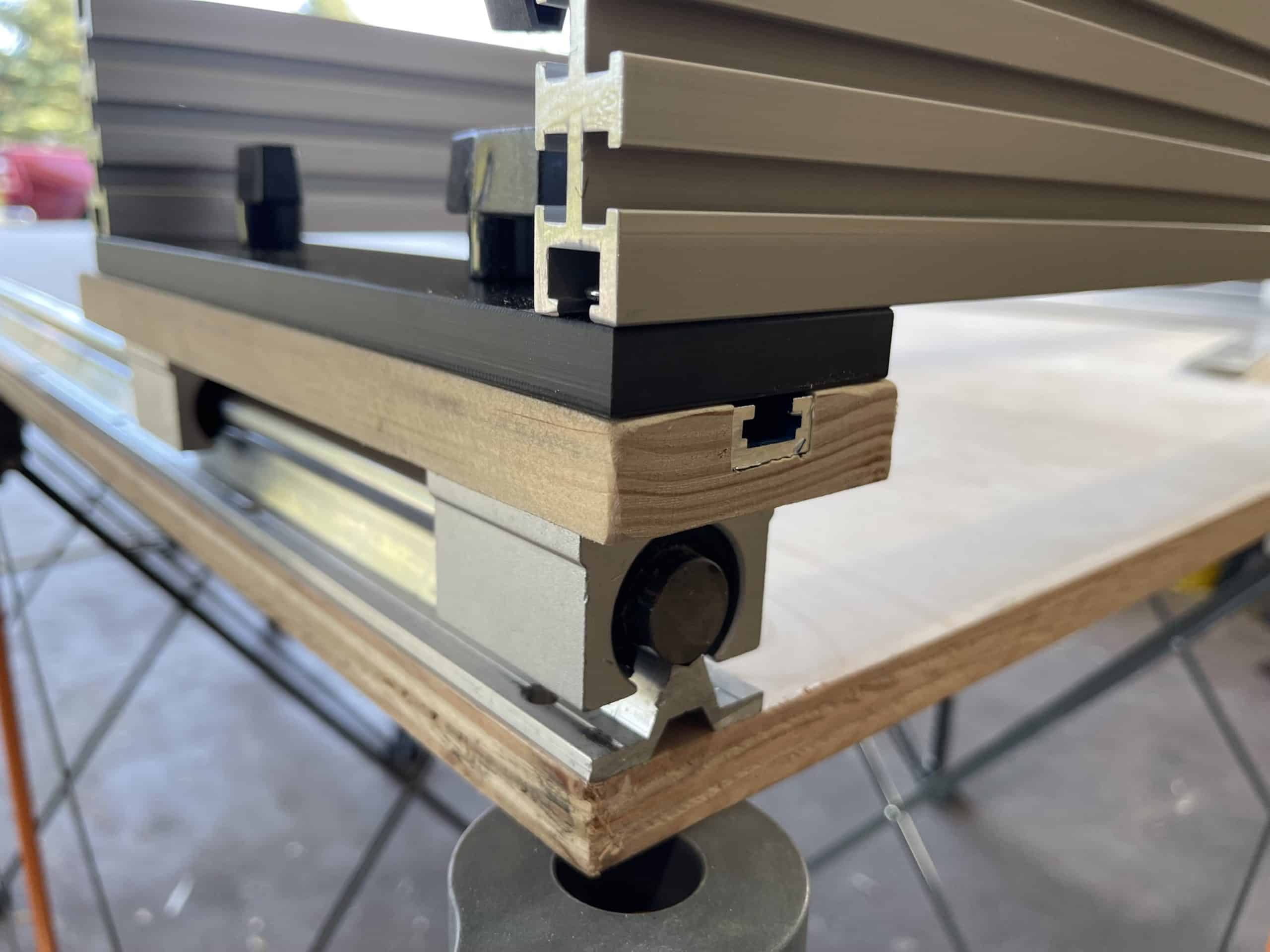

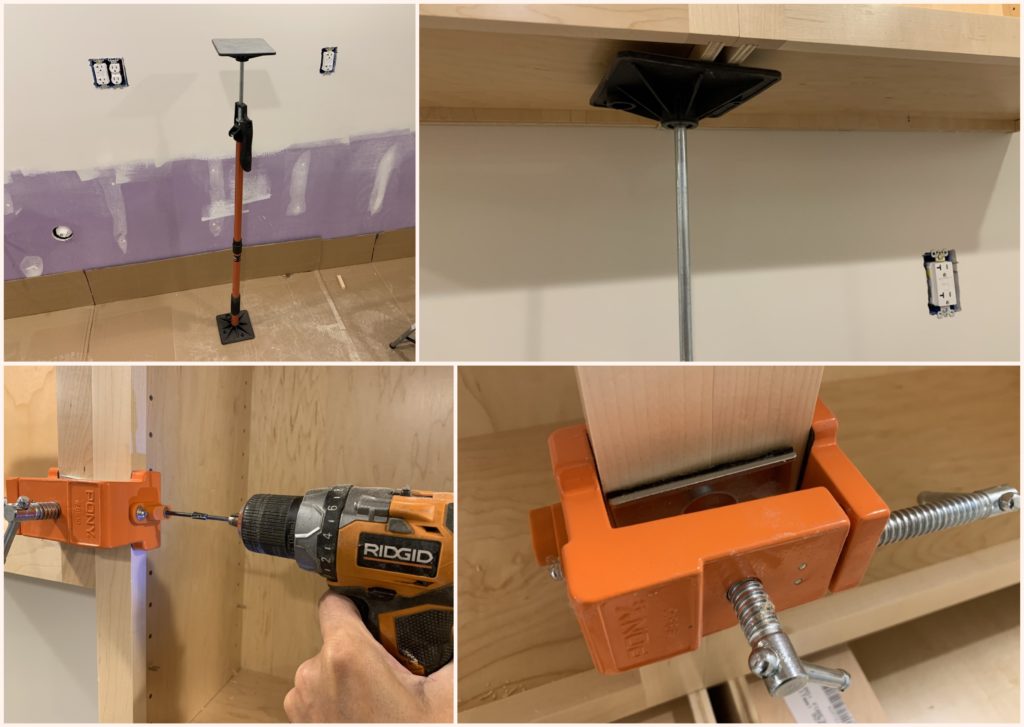

Step 8: Properly Attaching Your Top

One of the lessons new woodworkers quickly understand is that wood absorbs moisture. And only sometimes evenly.

So what does that mean to a wood top? Well, besides following the tip on finishing the wood top the same top and bottom, be sure to:

- First, securely attach the top so it cannot shift and support the weight of the structure below when used as a lifting point.

- Second, wood tops need room to move by using slotted clips that allow for movement.

- Always pre-drill screws in hardwood.

- make sure your screws are long enough to provide a firm connection but short enough not to go through the top.

Frequently Asked Questions

How do you seal a wood top?

Due to their size and tendency to warp, sealing a wood top requires applying the same finish equally on all six sides. The choice of sealer will depend on the wood and intended use; however, a penetrating sealer is usually best to draw out the color of the wood and protect the top surface. For tops that won’t be in direct contact with food, a final top coat with UV and water resistance, such as urethane, will protect the surface. And for food, contact tops like butcher blocks, a mineral or tung oil labeled food safe is best.

How do you join wood to form a table top?

The best method to join wood top pieces is by first jointing the wood to ensure a perfectly flat match, applying woodworkers glue, and then using clamps. While some DIY’ers opt for pocket hole screws, they are inadequate to correctly assemble a top and take longer.

How thick should a wood top be?

The top’s thickness should, first and foremost, match the overall project. For example, a large dining table can support a thickness of up to 2 inches. Meanwhile, a small coffee table might be best at a standard 3/4-inch. In general, structural integrity calls for a thickness of at least 3/4-inch, and many woodworkers will opt for a top between 1-1/4 and 1-1/2. The downside of thickness is also weight, which must be planned for.

Conclusion

While a custom wood top requires planning, a bit of woodworking knowledge, and tools, most DIY’ers will enjoy the result for years. And, based on your finish of choice, care for your top over time by re-applying mineral oils for a non-sealed finish or saving the brand and product used for finished tops.

- About the Author

- Latest Posts

Eric has been a professional woodworker for over thirty years and has worked in small cabinet shops making everything from kitchen cabinets to hand-made furniture. Now working from a home woodworking shop Eric is sharing his passion for woodworking, tool advice and how-to knowledge from his Minnesota-based woodshop.